This content is restricted to site members. If you are an existing user, please log in. New users may register below.

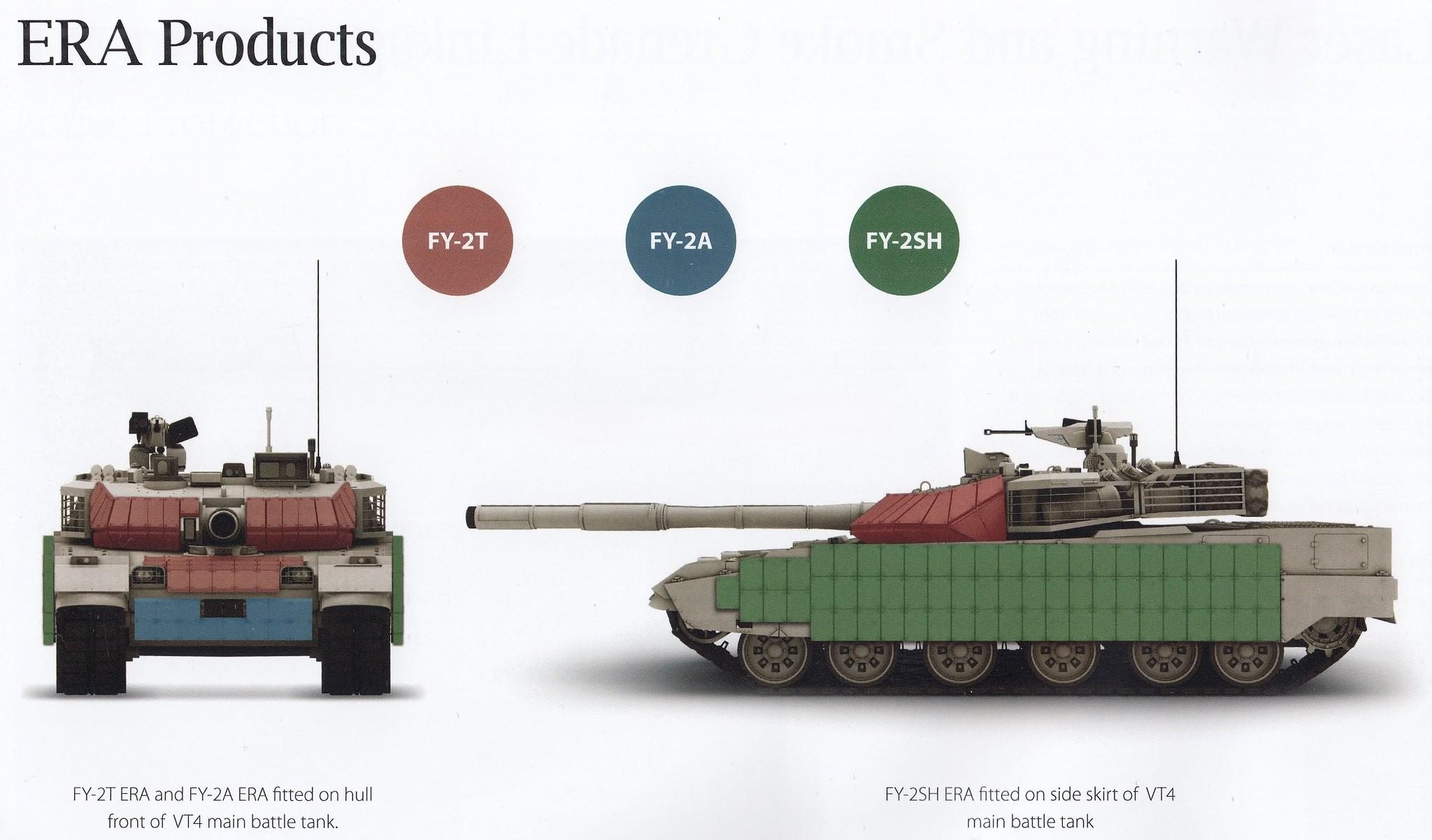

Chinese Armour Technology: The FY-2 Family

Reading Time: 3 minutes China’s modern tank protection philosophy has evolved rapidly over the past two decades, reflecting a shift towards modularity, layered defences and field-level maintainability. The FY-2 family of explosive reactive armour (ERA) — comprising the FY-2A, FY-2T and FY-2SH variants — exemplifies this approach. Designed for flexibility and cost-effectiveness, these armour modules have become a key component on both domestic and export main battle tanks, including the Type 96, Type 99 and VT series. Explosive Reactive Armour: China’s Practical Shield Explosive reactive armour works by sandwiching an explosive layer between two metal plates. When struck by a shaped charge or kinetic energy penetrator, the explosive detonates, driving the plates outward and disrupting the incoming jet or rod. This dramatically reduces the penetration effect before it reaches the underlying composite or steel armour. China employs ERA extensively because it provides a significant boost in protection for relatively little